In the dynamic world of industrial material processing, the efficiency and reliability of equipment can make or break productivity. One piece of machinery that has emerged as a cornerstone in industries like mining, construction, recycling, and quarrying is the OEM hydraulic crusher. These machines, engineered with precision and innovation, are revolutionizing how we process materials. Let's delve into the fascinating world of OEM hydraulic crushers and explore why they are becoming a hot topic in the industry.

What is an OEM Hydraulic Crusher?

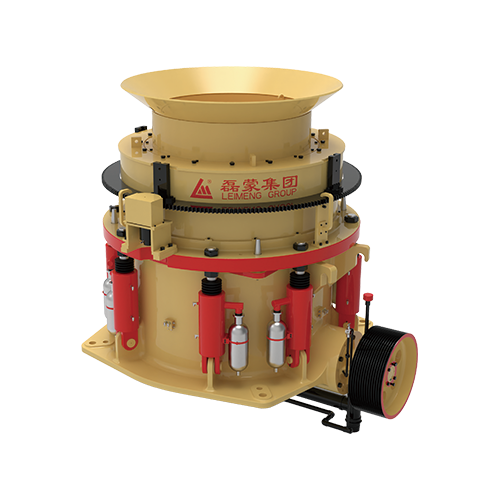

An

OEM hydraulic crusher is a type of heavy machinery designed and manufactured by the original equipment manufacturer (OEM) to crush various materials using hydraulic power. Unlike generic or aftermarket alternatives, OEM hydraulic crushers are built with advanced engineering and technology to ensure superior performance, durability, and efficiency. These crushers utilize hydraulic systems to replace traditional mechanical linkages, providing smoother operation and finer control over the crushing process.

The Engineering Marvel Behind OEM Hydraulic Crushers

At the heart of an OEM hydraulic crusher is a sophisticated hydraulic system that offers several advantages over conventional mechanical systems. Here are some key features that set them apart:

-

Dynamic Adjustment: Hydraulic cylinders allow operators to adjust the crusher's settings in real-time, adapting to the hardness, size, and feed rate of the material without stopping operations.

-

Overload Protection: Advanced hydraulic safety valves automatically relieve pressure during jams or encounters with uncrushable materials, preventing catastrophic failures.

-

Energy Efficiency: By optimizing hydraulic fluid flow, OEM designs can reduce power consumption by up to 20% compared to traditional crushers.

Moreover, leading manufacturers integrate smart sensors to monitor wear parts, ensuring timely maintenance and minimizing unplanned downtime.

Key Benefits of OEM Hydraulic Crushers

The popularity of OEM hydraulic crushers can be attributed to their numerous benefits:

-

Precision and Consistency: Hydraulic systems ensure uniform particle size distribution, which is critical for producing high-quality aggregates or meeting strict mineral processing specifications.

-

Custom-Built Solutions: OEMs tailor their crushers to meet the unique challenges of different sites, whether it's crushing abrasive granite, recycling concrete in urban environments, or processing soft limestone.

-

Long-Term Cost Savings: Although the initial cost may be higher, OEM crushers offer a lower total cost of ownership. Their robust construction reduces the frequency of part replacements, and warranties often cover critical components for years.

-

Seamless Integration: OEMs design crushers to work harmoniously with screening plants, conveyors, and other equipment, streamlining workflows and boosting overall system efficiency.

Diverse Applications of OEM Hydraulic Crushers

The versatility of OEM hydraulic crushers makes them indispensable across various industries:

-

Mining and Mineral Processing: In mining, OEM hydraulic cone crushers excel at reducing large ore chunks into finely graded material. For example, a copper mine in Chile saw a 35% increase in processing capacity and a 15% drop in energy costs after upgrading to an OEM hydraulic crusher.

-

Construction and Demolition Recycling: These crushers turn urban construction waste into reusable aggregates, supporting circular economy goals. A recycling plant in Japan achieved 90% material recovery rates using an OEM hydraulic crusher.

-

Quarrying and Aggregate Production: Quarries rely on OEM hydraulic crushers to produce uniformly sized stones for roads, bridges, and buildings. Their ability to handle fluctuating feed sizes and hardness levels ensures consistent output.

-

Specialty Applications: From crushing glass for industrial reuse to processing slag in steel plants, OEM hydraulic systems adapt to niche requirements. One innovative example is a European manufacturer that developed a noise-dampening hydraulic crusher for urban recycling centers.

How to Choose the Right OEM Hydraulic Crusher?

Selecting the ideal crusher requires a strategic approach. Here are some steps to consider:

-

Analyze Material Properties: Consider the hardness, abrasiveness, and moisture levels of the material to be crushed.

-

Define Operational Goals: Determine your target throughput, desired product size, and mobility needs (stationary vs. portable crushers).

-

Evaluate Manufacturer Credentials: Look for an OEM with ISO certifications, a global service network, and proven experience in your industry.

-

Test Before Investing: Many OEMs offer on-site trials or virtual simulations to demonstrate how their crusher performs with your specific material.

Maintenance Strategies for Peak Performance

Maximizing the lifespan of your OEM hydraulic crusher depends on proactive care:

-

Daily Checks: Inspect hydraulic hoses for leaks, monitor fluid temperature, and ensure lubrication points are greased.

-

Predictive Maintenance: Use IoT-enabled sensors to track vibration, pressure, and wear patterns. Predictive analytics can flag issues before they cause downtime.

-

Component Replacement: Always use OEM-approved parts. Generic alternatives may seem cheaper but often fail prematurely, risking collateral damage to the crusher.

-

Operator Training: Ensure staff are trained by the manufacturer to avoid misuse, such as overloading the chamber or ignoring error alerts.

Sustainability and Innovation in OEM Hydraulic Crushers

As industries prioritize ESG (Environmental, Social, Governance) goals, OEM hydraulic crusher manufacturers are rising to the challenge:

-

Energy Recovery Systems: Some crushers now capture kinetic energy during crushing cycles and convert it into reusable power for auxiliary systems.

-

Eco-Friendly Hydraulic Fluids: Biodegradable fluids reduce environmental risks in case of leaks.

-

Modular Designs: OEMs are creating crushers with replaceable modules, extending equipment life and reducing waste.

Future Trends: Smart OEM Hydraulic Crushers

The future of OEM hydraulic crushers is driven by digital transformation:

-

AI-Powered Optimization: Machine learning algorithms analyze historical data to recommend ideal crusher settings for different materials, boosting efficiency by up to 25%.

-

Remote Operation: With 5G connectivity, operators can control crushers from centralized hubs, reducing the need for on-site personnel in hazardous environments.

-

Blockchain for Supply Chains: Leading manufacturers are using blockchain to track part authenticity and maintenance history, ensuring transparency for buyers.

Case Study: Transforming a Limestone Quarry with OEM Hydraulic Crushers

A quarry in Texas upgraded to an OEM hydraulic cone crusher designed for high-abrasion environments. The results were impressive:

-

50% longer liner lifespan due to advanced hydraulic pressure management.

-

30% faster cycle times from automated gap adjustments.

-

Zero unplanned stoppages in the first year, compared to 8-10 incidents annually with the previous crusher.

The quarry manager noted, "Partnering with an OEM wasn't just about buying a machine—it was about future-proofing our operations."

Why OEM Partnerships Are Non-Negotiable

In a world where downtime costs thousands per hour and sustainability is a competitive advantage, OEM hydraulic crushers are more than just equipment—they are strategic investments. By collaborating with a trusted manufacturer, businesses gain access to cutting-edge technology, tailored solutions, and end-to-end support. Whether you're crushing diamonds in Botswana or recycling concrete in Manhattan, OEM hydraulic crushers deliver the precision, reliability, and innovation needed to thrive.

Ready to Elevate Your Crushing Operations? Contact us today and discover how hydraulic technology can transform your productivity—and bottom line.